How to Manage Hazardous Substances and Goods

A hazardous substance is any liquid, powder or vapour that contains a concentration above the acceptable legislated level and can cause harm, e.g. cleaning chemicals, paint and glue. The degree of harm caused depends upon what the substance is made of, the way it enters the body (e.g. through inhalation, ingestion) and the amount of substance that enters the body. Harm can occur due to:

-Overuse of chemicals.

-Mixing of chemicals.

-Improper use of the substances, i.e. without protection, in confined spaces or on wrong surfaces.

-Flammability of the materials used.

Hazardous goods may include electrical equipment, flammable goods and waste.

Controlling Hazardous Substances and Goods

A Material Safety Data Sheet (MSDS) provides detailed information on a hazardous substance or good. It gives more details than a label. MSDSs are provided to the store by the manufacturers and suppliers of hazardous substances or goods.

An MSDS will typically include the following details:

-The product name of the dangerous goods or hazardous substance.

-The name, address and telephone number of the Australian manufacturer or importing supplier.

-Australian telephone number for information in the event of an emergency.

-The date the MSDS was prepared or last reviewed.

-A statement that the substance is a hazardous substance (if applicable).

-The proper shipping name, UN number, class, subsidiary risk and packing group for dangerous goods.

-The hazard classification for hazardous substances.

-The risk and safety phrases for hazardous substances.

-The proportion or proportion ranges of the ingredients required to be identified with a chemical or generic name.

-First aid measures.

-Emergency procedures.

-Any relevant health hazard information.

-The chemical and physical properties of the substance or its ingredients including any hazardous decomposition products likely to be generated during normal use.

-Precautions for the safe use of the substance, including engineering controls and personal protective equipment.

-Precautions for the safe storage and disposal of the substance.

-The exposure standard (if any) for a hazardous substances or its ingredients.

-Information on the health effects of the substance or its ingredients.

Team members need to read the MSDS before they use a product. It is important that hazardous substance and goods in workplaces are used according to:

-The manufacturer or supplier’s written instructions, the MSDS.

-Agreed safe work procedures.

Team members need to:

-Follow safe work procedures.

-Always correctly wear the appropriate safety equipment (PPE).

-Wash exposed areas with soap and water before going to the toilet or eating and drinking.

The WHS Concerns Regarding Manual Handling

Manual handling is any activity where an individual uses force to lift, hold, lower, push, pull, carry or otherwise move or restrain an object.

Manual handling includes stacking shelves, stacking cartons on pallets, moving trolleys, and packing stock. Placing boxes and other items on shelves, painting, gardening, cleaning, writing and typing are some examples of manual handling tasks.

Manual handling is a major health and safety concern in a majority of retail stores. Following correct manual handling principles can help:

-Prevent the occurrence of injury resulting from manual handling tasks.

-Reduce the severity of injuries arising from manual handling tasks such as: strains and sprains, neck/ back injury, slips, falls and crush incidents and cuts, bruises and broken bones.

-Assist persons with a duty of care to identify, assess and control risks to health and safety arising from manual handling tasks.

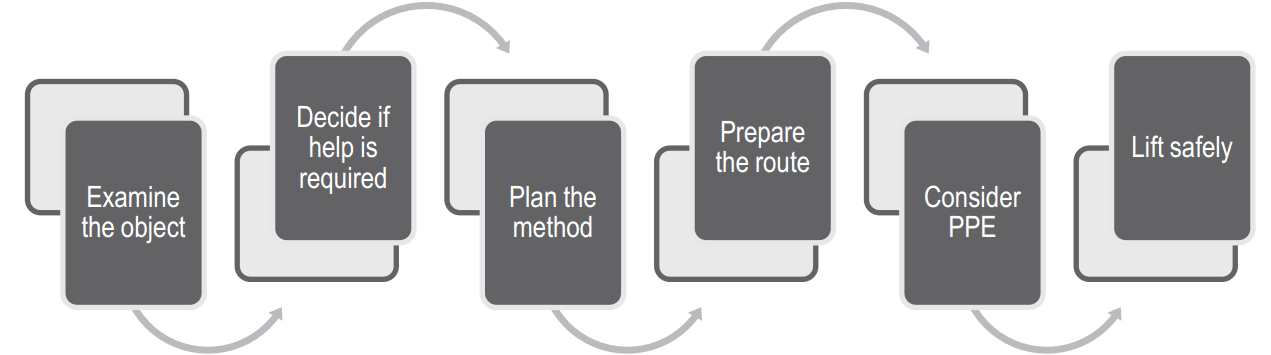

When performing manual handling tasks it is important to follow these key steps:

When lifting individuals should keep their back straight, feet apart, bend their knees and lift with their legs.

Looking to learn the art of effective Strategising? The ARA Retail Institute provides leading accredited training options including workshops and masterclasses in developing an effective merchandising strategy. Have a look at our classes below:

{{cta(‘9c8ef3db-89f9-4d9c-b4c0-bfd5d0a76556’)}} {{cta(‘9f97379c-6727-4d1e-8d11-7100c464a830’)}} {{cta(‘9f097306-d766-4cb6-ae6c-15ddc8b0718e’)}}